MECHANICAL INTEGRITY

The main focus of Fitness-For-Service analysis is evaluating whether an equipment has downgraded in service and can carry on its intended function properly.

This approach comprises in a rational decision process, enabling the engineer to decide whether the system can be controlled safely either as is, with reinforced inspection, after a requalification, or after a service or repair.

THE IMPLEMENTATION CONDITIONS

Fitness for service can be applied when:

- The equipment design is not fully compliant with the relevant codes.

- The equipment experienced an impact in service, during handling or in transit.

- The non-destructive testing and equipment inspection have noticed defects beyond the admissible limits or those that have happened too early.

- The equipment has never been examined, or only partly; the equipment acquired is old.

YOUR NEEDS

- Feasibility of avoiding to remove the equipment from service prematurely which should only have to be returned at term.

- Financial solution which is more economical than the replacing of the equipment.

- Creating an administrative file to obtain a derogation.

- Optimal utilization of the equipment based on precise assessment of its abilities.

YOUR ADVANTAGES

IRC’s Fitness-for-Service (FFS) engineering assessment is a multi-disciplinary method for assessing mechanical components to decide if they are fit for continued service.

The typical result of an FFS evaluation is a “go/no-go” decision on continued operation. An assessment of remaining life or examination intervals may also be part of such an evaluation, along with remediation of the degradation mechanism.

IRC’s methodology is based on the approach executed by a team of engineers who specialize in pressurized equipment technology, corrosion, material, structural analysis and inspection. The statutory requirements concerning the equipment are also taken care of.

OUR OFFER

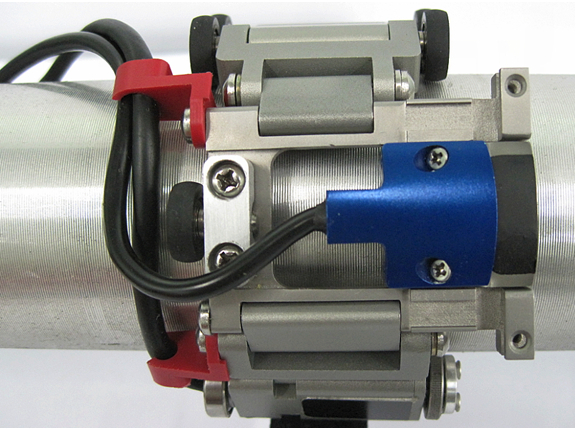

- Based on non-destructive testing, the Fitness for service methodology includes the following steps:

- Equipment integrity and residual life linked to kinetics,

- Guidance concerning the integrity due to future conditions.

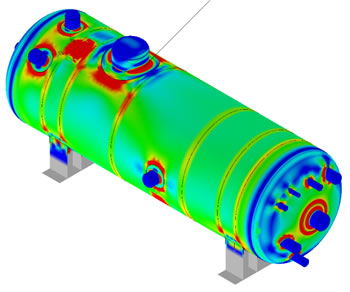

- Pressurized equipment (reactor, heat exchangers, columns, LPG tanks),

- Offshore pipelines & risers.

- Onshore pipelines,

- Atmospheric storage tanks which includes cryogenic (LNG),

- The methodology can be expanded to other equipment depending upon the circumstance.

- The damage mechanisms correlate to the below non-restrictive list:

- Stress Corrosion Cracking (SCC),

- Metallurgical damages (embrittlement, intermediate phases)

- Localised corrosion, whether general, under insulation or pitting

- Fatigue (thermal or mechanical),

- Creep,

- Crack-like flaws

SERVICE HIGHLIGHTS

Here are the features of FFS and Remaining Life:

- Flaw Type Detection: This includes-

- Corrosion

- Brittle fracture

- Fatigue

- Crack-like flaws

- Creep

- Hydrogen embrittlement

- Stress corrosion cracking

- Dents and shell deformations

- High-temperature hydrogen attack

2. Fitness for Service Application: This includes-

- Fired heaters

- High-energy piping

- Turbines

- Pipelines

- Power lines

- Headers

- Pressure vessels

- Storage tanks

3. Advanced Creep Testing: Remaining Life Assessment Based on Creep Testing – IRC’s advanced creep testing service includes reliable and accurate life assessment of components prone to creep damage. This facility provides a higher level of accuracy when it comes to life assessment techniques based on actual creep property of components. Creep testing assessments lets operators optimize operating conditions, decide effective inspection intervals and extend component life.

IRC has carried out numerous projects for FFS on Piping operating at Temperature of Creep.

4. Pipeline Defect Assessment: IRC has a unique combination of major industry fracture mechanics expertise with integrity management experience, data analysis and software.

Our integrity management tools help us to support our clients with consulting and software solutions whether they are handling anomaly response plans, fitness-for-service assessments strain analysis of dents and deformations or failure analysis.

About IRC Engineering Pvt. Ltd.

IRC is one of the fastest growing Testing and Inspection company in India. We at IRC provide Non-Destructive Testing, Destructive Testing, Advanced NDT, Third Party Inspection, Condenser Testing, Electrical Testing, Residual Life Assessment of Power Plant, O&M Services, Fitness For Service, Civil Testing and Training services.

read more IRC Engineering Services

IRC Engineering Services

Recent Comments